Weld-through primer application is a game-changer in automotive collision repair, enhancing structural integrity through robust metal fusion bonds. This method, widely used for dent repair, offers benefits like enhanced adhesion, corrosion protection, and increased repair longevity under extreme conditions. By reducing warranty claims and boosting customer satisfaction, auto body shops can solidify their reputation for high-quality services. Proper application requires thorough surface prep, welder's mask, precise control, even coverage, consistent thickness, and adequate drying times to ensure superior results and minimize post-repair defects.

Weld-through primer application is a game-changer in manufacturing, significantly reducing warranty claims. This article delves into the multifaceted benefits of this technique, starting with an in-depth understanding of weld-through primer: its role, advantages, and how it fortifies bond strength. We explore the substantial impact on warranty claims, highlighting its error-minimizing capabilities and defect reduction. Furthermore, best practices for application are provided to ensure longevity and optimal results.

- Understanding Weld-Through Primer: Its Role and Benefits

- The Impact on Warranty Claims: How It Minimizes Errors and Defects

- Best Practices for Effective Application: Tips and Techniques to Ensure Longevity

Understanding Weld-Through Primer: Its Role and Benefits

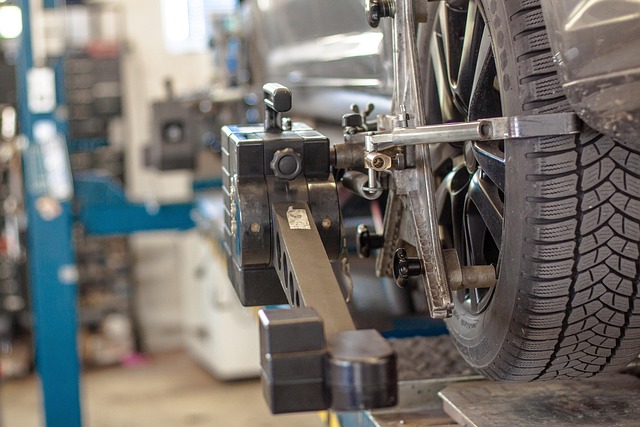

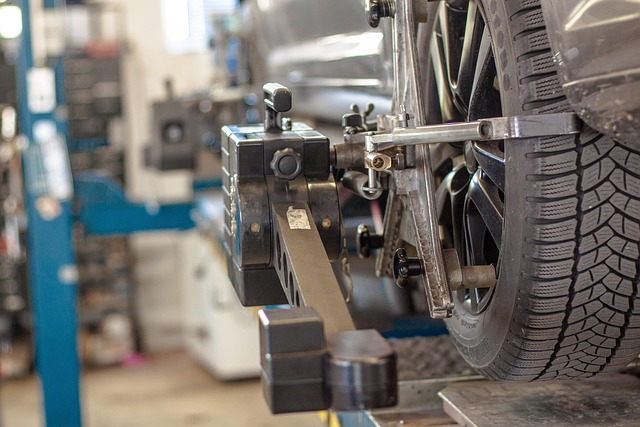

Weld-through primer is a specialized coating designed to facilitate the fusion of metal during the welding process. Its primary role is to create a robust bond between the base material and the weld, ensuring structural integrity. This innovative application method has gained significant traction in the automotive industry, particularly in vehicle dent repair and collision repair services. By applying weld-through primer before the welding process, professionals in auto frame repair can achieve enhanced adhesion, resulting in more durable and aesthetically pleasing repairs.

The benefits of weld-through primer application extend beyond improved weld strength. It also acts as a protective barrier, preventing corrosion and ensuring the longevity of the repaired area. This is especially crucial in the dynamic environment where vehicles operate, with varying temperatures and exposure to elements that can compromise the integrity of repairs over time. By integrating weld-through primer into collision repair services, auto body shops can reduce warranty claims related to poor workmanship or structural failures, ultimately enhancing customer satisfaction and boosting their reputation for high-quality vehicle dent repair.

The Impact on Warranty Claims: How It Minimizes Errors and Defects

The implementation of weld-through primer application significantly reduces warranty claims within the automotive collision repair industry. This advanced technique is instrumental in enhancing the quality and longevity of vehicle repair, thereby minimizing errors and defects that often lead to costly post-repair issues. By strategically applying a protective coating directly onto bare metal surfaces before welding, this method creates a robust bond that prevents corrosion and ensures structural integrity.

This meticulous process, when incorporated into auto repair shop practices, serves as a game-changer in the realm of automotive collision repair. It addresses the root causes of many warranty claims by eliminating potential problems associated with poor weld quality, improper material compatibility, and environmental factors that can compromise the durability of repairs. As a result, weld-through primer application fosters higher customer satisfaction levels and reduces financial burdens for both repair shops and vehicle owners in the long run.

Best Practices for Effective Application: Tips and Techniques to Ensure Longevity

When it comes to weld-through primer application, best practices are key to ensuring its effectiveness and longevity in car damage repair or vehicle repair. Start by preparing the surface thoroughly; this includes cleaning, degreasing, and removing any debris or contaminants. A smooth, dry surface is essential for optimal adhesion. Use a dedicated welder’s mask to protect against sparks and heat during the application process.

For precise results, control the application rate and ensure even coverage. Maintain a consistent thickness, avoiding both thin spots and overapplication. Allow adequate drying time between coats as recommended by the manufacturer. Proper curing is crucial for achieving maximum bond strength and long-lasting protection. Remember, these practices not only enhance the durability of the weld but also contribute to reducing warranty claims associated with body shop services.

Weld-through primer application is a game-changer in manufacturing, significantly reducing warranty claims by minimizing errors and defects. By understanding its role, implementing best practices, and leveraging its benefits, companies can enhance product longevity and customer satisfaction. This strategic approach ensures that welds are robust, durable, and free from issues, ultimately fostering a positive brand image.